WHY IS INS A LEADING SUPPLIER OF CUSTOM FIBER OPTIC ASSEMBLIES?

1. FLEXIBILITY

- Wide Selection of components from leading manufacturers

- Ability to build to Engineering specifications or drawings

- From a quantity of 1 or 1,000’s INS can deliver

2. FAST DELIVERY / HIGH QUALITY

- Cables are ready to ship nationwide and internationally in as little as 2-4 days

- 100% inspection and tested to industry standards

- Over 25 years of cable assembly experience

3. ADDITIONAL SERVICES

- Termination of customer supplied materials

- Creation of engineer drawings of assemblies

- Custom packaging, custom labeling

- Experienced engineering team to help design an assembly for any application

STANDARD CONFIGURATIONS

Standard configurations (typical lead-time 2-4 days) – Convert your next project to “plug n’ go” by having your cable assemblies pre-terminated by INS. Our expert technicians prepare assemblies from a 1-fiber patch cable to 144-fiber assemblies, while offering a wide array of components for you to create the perfect assembly for your application.

CUSTOM CONFIGURATIONS

Custom configurations (typical lead-time 3-5 days) – INS has the ability to manufacture a variety of custom configurations. Our custom abilities include but are not limited to labeling, packaging, testing requirements, and building to customer supplied specifications and drawings

CONFIGURATION ILLUSTRATION

CLIPPED DUPLEX PATCH CABLE

Standard Polarity A to B / B to A

SIMPLEX PATCH CABLE

UNCLIPPED DUPLEX PATCH CABLE

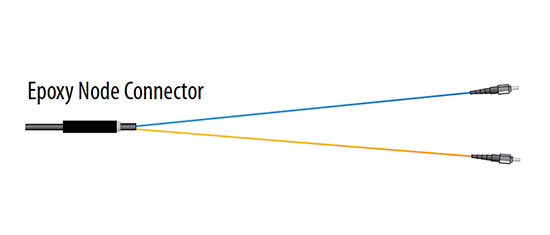

NODE CABLE ASSEMBLY

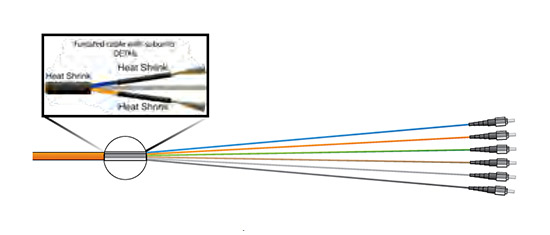

DISTRIBUTION - INDOOR/OUTDOOR ASSEMBLY

2-144 Fiber (ex. 6 Fiber Assembly)

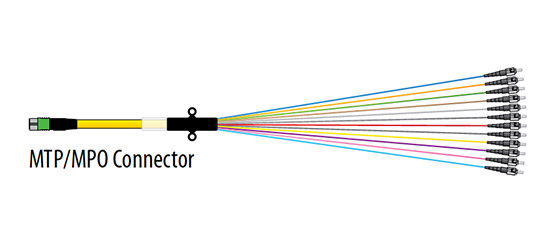

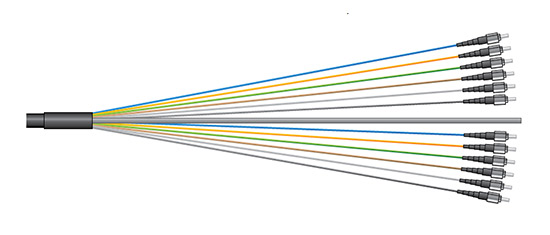

RIBBON FANOUT ASSEMBLY

LOOSE TUBE CABLE ASSEMBLY

Cable Construction Types

SIMPLEX- A single fiber cable that may consist of a 900μm coated fiber or a combination of a 900μm coated fiber surrounded by an aramid yarn strength member with an outer jacket diameter varying from 3, 2, 1.8 and 1.6mm.

DUPLEX - A two-fiber cable that consists of a combination of two 900μm coated fibers surrounded by an aramid yarn strength member with an outer jacket diameter varying from 3, 2, 1.8 and 1.6mm. Also can choose 900μm duplex cable where the two 900μm buffers are joined together.

(Limited offering from manufacturers.)

BREAKOUT - Packages multiple 2.5-3.0mm jacketed fibers and surrounds these sub-units with an aramid yarn strength member and outer jacket. Fiber counts typically are 2-24 fibers. Primarily used in application where a rugged or robust cable is required.

DISTRIBUTION - Packages multiple 900μm tight buffered fibers, surrounded by aramid yarn strength member, in a larger outer jacket. Fiber counts typically range from 2 – 144 fibers. Primarily used indoors and popular with interlocking armor for extra protection. Often referred to as MIC cable construction by other manufacturers.

MICRO-DISTRIBUTION - Packages multiple 250μm buffered bare fibers of different colors within subunits to minimize the outer jacket size. Fan-out kits or furcation tube often required to terminate connectors. Popular for indoor use with MTP/MPO connector and Fan-out assemblies in Data Center applications.

BARE FIBER - A single glass fiber typically consisting of a core, cladding and 250μm acrylate coating.

TIGHT BUFFER - A single bare fiber with an outer coating that is typically 900μm in diameter.

LOOSE TUBE - Packages 250μm buffered fibers amongst each other in gel filled sub units typically 2.0-2.5mm. The gel filled tubes provide superior protection against changing temperatures and water filled conduits. Outer jacket is UV and moisture resistant.

LOOSE TUBE ARMORED - Packages 250μm buffered fibers amongst each other in gel filled sub units typically 2.0-2.5mm. The gel filled tubes provide superior protection against changing temperatures and water filled conduits. The outer jacket is extruded over corrugated coated steel tape offering rodent proof protection, the jacket is UV and moisture resistant.

OUTDOOR DRY (GEL FREE) CABLE - Packages 250μm buffered fibers within super absorbent polymer or water treated blocking aramid yarn. Dry loose tube design improves ease of termination without gel filled tubes. Recommended for installation in ducts, underground conduit or aerial/lashing applications not intended for direct burial. Armored version of cable utilizes corrugated coated steel tape for rodent protection, with extruded UV resistant jacket.

DISTRIBUTION INTERLOCKING ARMORED - Available with Riser or Plenum rated outer jacket this cable houses 900μm buffered fibers surrounded by aramid yarn with interlocking aluminum armor then extruded outer flame resistant jacket. Intended for harsh indoor environments requiring heavy duty protection.

TACTICAL CABLE - Packages typically multiple 2.0-2.5mm jacketed subunits surrounded by aramid yarn with epoxy/fiberglass strength member. Rugged design for heavy duty applications such as TV cameras, mining/harsh environments and military/commercial field re-deployable communications. Tactical Distribution packages 900μm fiber rather than larger subunits.